Case Studies

Troubleshooter Guided Diagnostics

Product: Troubleshooter Guided Diagnostics

Client: Major Utility Vehicle Manufacturer

High support center call volumes signaled trouble for technicians—until our groundbreaking Troubleshooter Guided Diagnostics tool changed the entire paradigm.

Overview

A world leader in farming & construction equipment needed a way to improve machinery uptime. Offline machines were becoming a concern for the company’s rental fleets and dealer service centers, with corporate call centers overburdened by support requests.

Tweddle Group transformed the company’s existing reference libraries into a fully interactive diagnostic platform, one which improved uptime and made field technicians more self-sufficient.

The Problem

Uptime is a huge concern for utility vehicles, and a critical priority in the rental market where machines only generate revenue if they’re in good working order.

In this environment, excellent technician support becomes essential. Rental centers and dealer service outlets employ their own technician staffs for maintenance and repair. These technicians are expected to work on a vast range of products from multiple manufacturers. Strong reference material empowers them to perform accurate repairs quickly, regardless of their experience level or familiarity with the products and issues involved.

Our client knew their service solutions were falling short. Calls from frustrated technicians deluged their support centers as complaints of chronic downtime poured in from rental centers.

- Improve machine uptimes for their rental centers

- Alleviate the burdens placed on their corporate call centers

- Increase the efficiency of their service operations

The Challenge

The manufacturer’s vast product range posed its own set of challenges:

- High product diversity

- High mechanical and electrical complexity

- Relatively low frequency of repeat failures

And the client’s service library was a hybrid of printed material and static digital sources where current material existed alongside outdated and still-valid legacy content. All this data would need to be vetted, ingested and tagged before anyone could apply machine intelligence to the data.

The Process

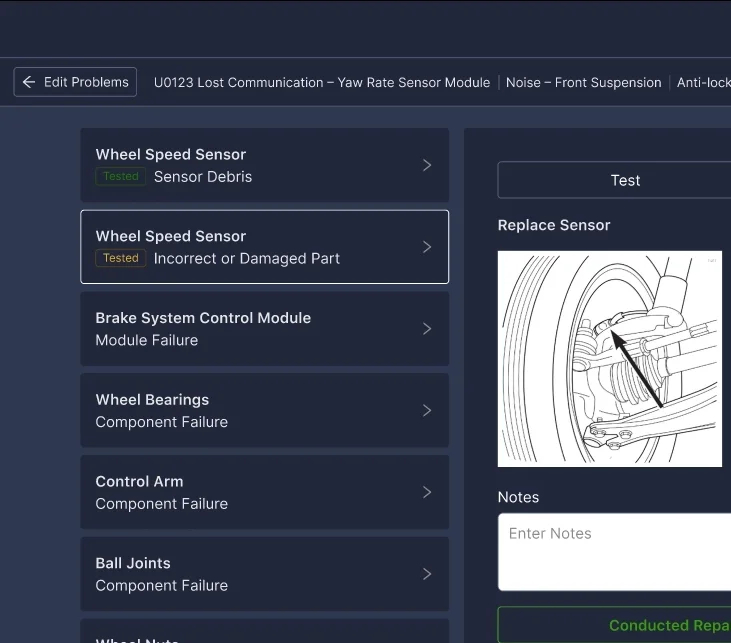

Troubleshooter, Tweddle Group’s guided diagnostic platform, offered the best solution for the client’s downtime issues and frustrated technicians. In the terms of a standard repair order (Complaint, Cause, Correction) this guided diagnostics platform lets the technician indicate a Complaint, quickly helps them identify the most-likely root Cause, then prescribes an appropriate Correction. It does this by guiding the user through a dynamic series of questions, measurements and tests to arrive at an accurate repair solution. Troubleshooter accelerates the repair process and offers substantial value to any technician not overly familiar with a particular machine.

To enable this solution, Tweddle Group teams structured, parsed and curated the client’s legacy service content, digitizing any necessary printed reference material.

TG content experts then performed a second line of manual validation to ensure content accuracy.

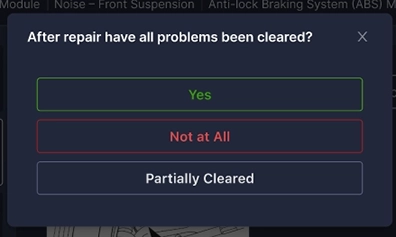

To address the issue of call center support requests, Tweddle Group created a proprietary tool aligned with client branding featuring a “gated” escalation option whereby a technician could only reach corporate support if they first followed the platform’s prescriptive diagnostic procedure. If a procedure fails, and the technician exercises this escalation, the Troubleshooter Guided Diagnostics system automatically attaches all session data to the service request for easy and immediate support team review.

The Solution

The client piloted the Troubleshooter Guided Diagnostics platform to a nationwide rental chain, one of their major partners, as a proof of concept. This roll-out created an immediate reduction in support requests and significantly improved machine uptimes.

Based on the proof of concept’s success, the client approved a production solution for the North America region, then deployed it globally to all regions worldwide.

The Result

Measured against the project’s initial goals, our Troubleshooter Guided Diagnostics solution brought the customer:

- 30% reduction in call volumes in Year One

- 9% reduction in call volumes, year over year in Year Two and Year Three

- A measurable reduction in average diagnostic times for technicians

The product achieved an 88% dealer penetration across North America with a steady increase in monthly usage rates.

As the solution spread into Europe, Asia, Latin America and the rest of the client’s global markets, it easily scaled to support the global presence, all while improving the product and extending the reach of its effectiveness.

One newer enhancement allows users to attach warranty claims, creating a record which ports easily into the warranty system. This had previously been done on an ad hoc basis without producing any clear document trail.

Troubleshooter also enhanced the client’s onboarding processes, where its theory of operation content helps create on-demand training opportunities.

Through it all, the Troubleshooter system incorporates the findings of each new diagnostic session, gathering intelligence and improving its speed and accuracy with every use.