When will DPP be mandatory? Why is it targeting the EV market first, and what should companies be doing now to prepare for its arrival?

In Part One of our interview, Mike Wahl, Tweddle Group’s VP of Software Engineering, AI & IT explained the mechanics of the Digital Product Passport, how it relates to sustainability, and the new demands it will place on manufacturers and their information reserves.

Next, we asked Mike about the DPP adoption timeline, how he expects DPP legislation to change the automotive industry-at-large, and what new competitive advantages he believes DPP offers for proactive OEMs.

What else will emerge from broadbased DPP adoption?

Well, another big feature is interoperability, which is the ability of two systems to share and understand information seamlessly between one another. Think about how your smartphone connects to any Wi-Fi network anywhere in the world.

Okay. Which is something I honestly never think about.

Right? So, your smartphone can go and join the network at work, at your house, the restaurant, the hotel, whatever. That’s possible because all the devices in that chain conform to the same standards.

That’s interoperability.

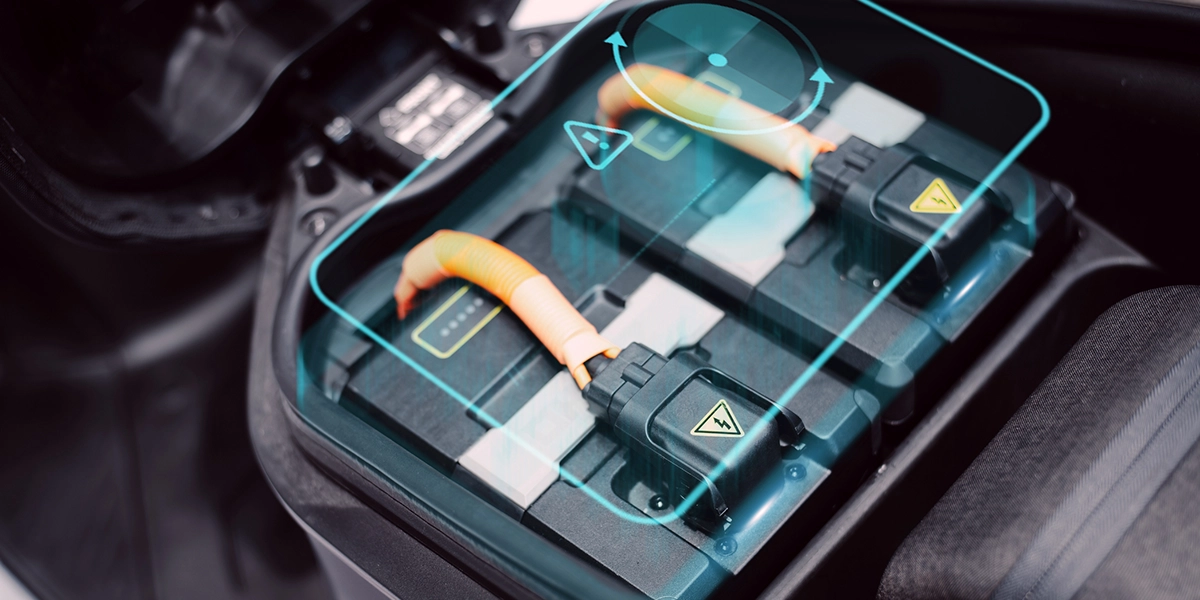

In the DPP context, it means an EV battery manufactured by a supplier in South Korea, installed in a vehicle assembled in Germany and eventually recycled in Canada can have its Digital ID-Passport data read and understood by systems in all three of those countries.

All these different systems can share that information and understand each other because we’re following a standard. They’re all conforming to the same communication method.

"DPP becomes mandatory in 2027 for EV and industrial batteries over 2kWh in the EU. 2028 to 2030, it expands to other vehicle components like electronics, textiles and plastics. "

If they weren’t, it would be a nightmare.

It would be a complete nightmare. There would be no way to read or transmit this information without a separate line of communication, and that’s not happening, right? (Laughs) So, DPP offers a pretty sharp solution: embed the data in the product itself and establish a standardized method for transmitting that information.

It’s easy to see the value in your example. Your hypothetical EV battery is interacting with people and systems in three different parts of the world, or potentially more when you look at the supply chains for the battery components.

Right. And, as it moves from one place to the other, it creates this ledger of what’s happening at each checkpoint, as it were. Where was it manufactured? Where was it installed? Where’s it being recycled? It’s all stored right in the product, or product component.

Plus, you might find other relevant data embedded along the way.

Let’s say I’m working at a disposal facility in Canada. I get this battery. How does it benefit me to know where it came from and what it did along the way?

Well, given the methods of its manufacture there could be something in there that could impact you, as the recycler. It might require a particular disposal method. It might need to be recycled, but in a particular way. There could be any number of things you should know about.

Do you see the auto industry benefitting from DPP in any way?

I think DPP is going to be crucial for automotive companies. Think about it. Vehicles contain thousands of components from hundreds of suppliers. Without interoperability, you’d need separate systems to track every component type. You’d have an operational nightmare.

With good interoperability, all your areas can work with the same data standards. So, supply chain management, quality control, end-of-life processing systems… they can all just plug in and do their part appropriately.

I think it’s going to help optimize supply chains by creating real-time visibility into component origins, quality metrics and sustainability credentials. Which, in turn, will open the door to better supplier decisions and risk management.

I might also bet we’ll see a bit of an explosion in data management systems and collaboration platforms, too, as everybody establishes methods for looking in on all the new information being generated.

Also, you know, risk mitigation. We’ll have better traceability. That’ll help prevent supply chain disruptions and enable faster response times to quality issues and recalls, things like that.

So, for OEMs, there are actual competitive advantages stitched into this push.

In my mind, absolutely. Companies that get ahead of this and implement it strategically, right, rather than just because they have to, will have a definite competitive advantage.

Those companies won’t just meet regulations, they’ll be more efficient, and they’ll develop better customer relationships.

They’ll also have a leg up in repair and service and things like that.

When Will DPP Be Mandatory?

What’s the timeline for DPP adoption?

Well, the early movers—the companies who use the 2027 battery requirement as a pilot program to build the infrastructure and capabilities needed for broader implementation—they’re going to have a head start.

Okay, 2027 is the first checkpoint. What comes next?

Battery passports become mandatory in 2027. That’s for EV and industrial batteries over 2kWh in the EU.

Then, from 2028 to 2030 it’s going to expand to other vehicle components like electronics, textiles and plastics.

Is the goal for DPP to apply to every component in the vehicle, then?

Potentially, yeah. Potentially.

And then, 2030 and beyond, we’re looking at full passport integration and potential expansion into other global markets.

Where do you think the greatest change will emerge from all this?

I think all the developments will be interesting, but I think the customer relationship is really going to evolve.

That relationship already extends beyond the point of sale. Obviously, right? But now we’ll see new opportunities for ongoing touchpoints. New service opportunities, as well.

I can see how a service bay would gain immensely from knowing anything there is to know about all the components making up a particular vehicle.

Absolutely. Think about Right to Repair and that whole landscape, and a world where every component in every product has that digital ID passport.

Just imagine an independent shop getting a vehicle where every component has that digital ID and the information that goes along with it. That could fundamentally change how service decisions get made. At the very least, it eliminates a ton of mystery for the independent technician.

Transforming Repair

Can you give me an example?

Consider a technician diagnosing some component or some problem on the vehicle. Are they going to repair the part or replace the part? Do they have the replacement parts on hand?

Those decisions are often based on really limited information, on the technician’s level of experience, right? Hopefully they’re using some guided diagnostics tool in the workflow here, but… still.

Right.

Now imagine that component’s a digital passport ID contains the manufacturing date, the material composition, potentially even its repair history. You might find or now be able to infer its remaining lifecycle, right? You can assess the environmental impact or repairing something versus replacing something. You could check the availability of necessary parts across the supply network.

Pretty different, right?

Indeed. It’s a whole different scenario.

Right? And that level of transparency doesn’t just help the individual repair shops. Imagine fleet management systems, automatically optimizing maintenance schedules based on real-time component data or diagnostic information.

Right. Slashing uptime with preventive maintenance.

Exactly. Another example might involve insurance companies, who have historically always assessed vehicles based on the VIN, the vehicle’s age, the milage, the superficial condition.

With DPP, they’ll be able to assess vehicles using verifiable data at the component level. That’s huge, man. It’ll become a whole different ballgame.

And that’s where things are headed toward. It’s really cool.

"Imagine fleet management systems, automatically optimizing maintenance schedules based on real-time component data or diagnostic information."

As products increasingly become complex systems in themselves, with different hardware and software having to communicate with one another, could DPP eventually identify compatibility issues? Not even just in vehicles, but I’m picturing a home workspace or studio environment, where if the whole system’s having issues, it might be able to say, “You need to update firmware X to eliminate a conflict with component Y.” That could eliminate tons of troubleshooting time.

Potentially, for sure. Things are moving so fast, especially on the AI front. As these technologies emerge, the question on everyone’s mind is, how do we consolidate? How do we bring all this together into one giant clockwork?

Naturally, with so many different countries and manufacturers in the mix, along with their own internal development teams, getting them all to find and agree on a good solution takes a lot of time.

But I could see what you’re describing taking place in the future. I could see DPP creating a more complete picture of everything that’s happening in terms of life cycle, you know, component interaction and diagnostics.

Do you see DPP moving into heavy machine and farm equipment or other areas like that?

I believe it will. I can’t predict the future, I don’t have a crystal ball. But I would imagine it won’t move into these other areas until it’s firmly established in the automotive space.

And even with automotive, it’s starting with EVs and EV batteries, and then it will move outward.

In terms of the number of components and complexity of the drivetrain, EVs are the ideal starting point. They’re less complicated than ICE (internal combustion engine) vehicles. I’m not saying they’re not complicated, but they’re certainly less complicated. There are fewer moving parts.

In Part 3 of our interview, we’ll look at what companies are doing to prepare their content for the new legislation, and why some organizations will be far more ready for DPP than others.

Mike Wahl photos by Matt Wong for the Tweddle Group Photography Team